In modern construction machinery equipment, the role of thermal management system is crucial, and heat exchanger is an indispensable core component of this system. Construction machinery usually operates in extreme environments such as high load, high temperature, high dust, and high vibration, such as excavators, loaders, bulldozers, cranes, etc., and their engines, hydraulic systems, air conditioning systems, etc. will generate a lot of heat. If the heat cannot be effectively dissipated, it will not only affect the performance of the equipment, but also cause system failures and even damage the equipment. Therefore, the performance of the heat exchanger of construction machinery is directly related to the working efficiency and service life of the equipment.

A heat exchanger is a device that realizes the transfer of heat energy between cold and hot fluids. In construction machinery, the main heat exchangers used include three categories: water-cooled, oil-cooled, and air-cooled:

Water-cooled heat exchanger: uses cooling water as a medium to absorb the heat of high-temperature components (such as engines), and then exchanges heat through the radiator. This method has good heat dissipation effect, but has high requirements on water quality and cooling system sealing.

Oil-cooled heat exchanger: Mainly used in hydraulic systems to transfer the heat of high-temperature hydraulic oil to the cooling medium. The stable operation of the hydraulic system is inseparable from an efficient oil cooler.

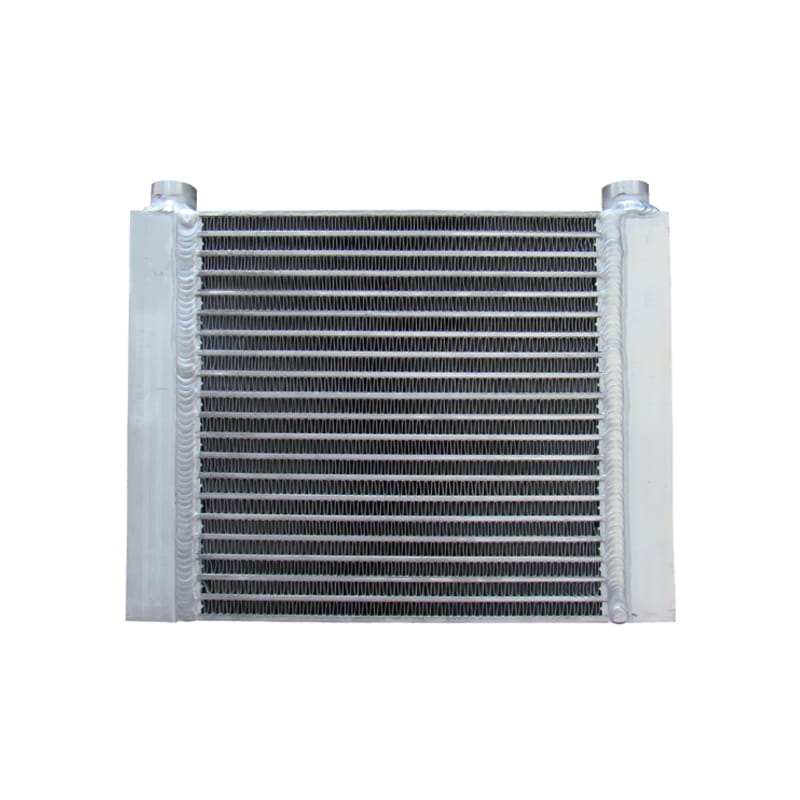

Air-cooled heat exchanger: uses a fan to blow air through the finned radiator to reduce the medium temperature. It is widely used in engineering equipment in high temperature and high dust environments.

According to different structures and heat transfer methods, heat exchangers can also be divided into plate type, fin type, shell and tube type, serial type and other types. Engineering machinery is mostly finned tube type, which has the advantages of small size, high heat transfer efficiency and easy installation.

High strength and durability

Engineering machinery operates in complex environments for a long time, and the heat exchanger needs to have good shock resistance and corrosion resistance. It is often made of aluminum alloy or copper alloy materials and treated with anti-corrosion.

Efficient heat dissipation capacity

In order to ensure the normal operation of the engine and hydraulic system, the heat exchanger must have high heat transfer efficiency, quickly export heat from the inside of the equipment, and maintain the system temperature stable.

Easy maintenance design

The structural design of the heat exchanger usually considers easy disassembly, cleaning and replacement to meet the actual maintenance needs of the construction site.

Customized solutions

Different types of construction machinery have different powers, structures and working conditions, and the required heat exchange solutions are also different. Many manufacturers provide customized designs to match the heat dissipation requirements of specific equipment.

Technology development trends

As construction machinery develops towards large-scale, high-power and multi-functional directions, the requirements for heat exchangers are also constantly increasing. Future development trends mainly include:

Application of high-performance materials: such as nano-coatings, anti-clogging fins, high-temperature resistant alloys, etc., to improve corrosion resistance and anti-pollution capabilities.

Intelligent control system integration: Through the combination of temperature sensors and control units, intelligent adjustment of the heat exchange system is realized to improve energy efficiency.

Modular design: convenient installation and maintenance, and improve the flexibility of the whole machine layout.

As the core of the equipment thermal management system, the performance of the construction machinery heat exchanger directly affects the reliability and efficiency of the whole machine. With the continuous development of mechanical technology, higher requirements are placed on the performance of heat exchangers. In the future, heat exchangers will continue to innovate in materials, structures and intelligence to ensure the efficient and stable operation of construction machinery.

English

English русский

русский